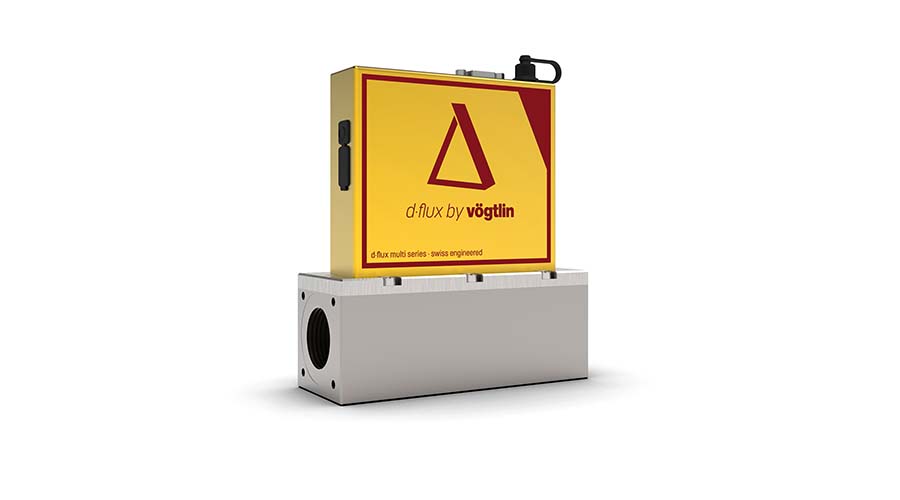

Multi-Parameter Mass Flow Meters & Mass Flow Controllers for Gases

The d·flux multi series is a fast and reliable multi-parameter mass flow meter for gases with measurement outputs for mass, volumetric and normalized flow, pressure and temperature. One of the many advantages of this laminar flow meter is the ability to easily switch to a different gas without a loss in accuracy.

Meter and Controller

Flow rates up to 1400 ln/min

Each range can be reduced by the user by 30% without any loss in accuracy (rate for air, other gases according to conversion)

Multiple pre-programmed gases

More gases can be added at any time

Wide application scope IP54

The body is in stainless-steel 316L and environmental protection is IP54

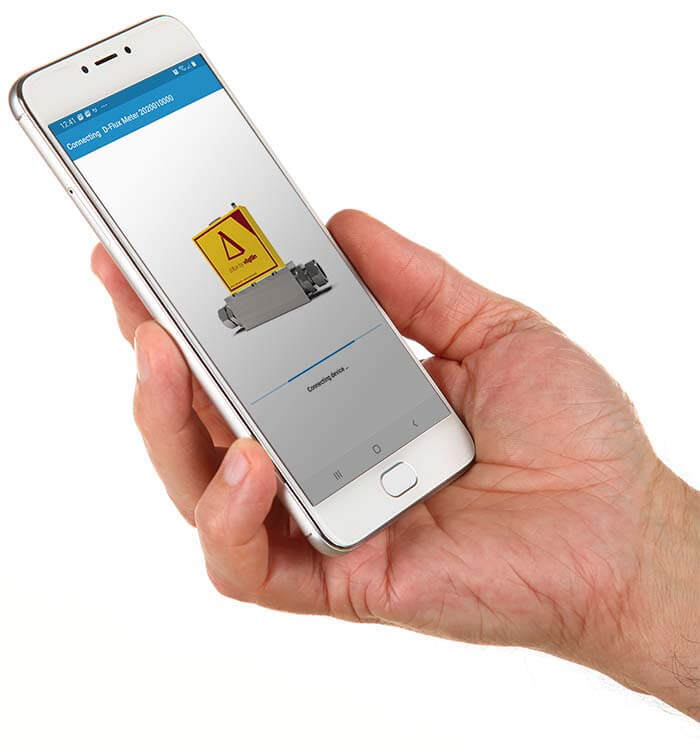

Wireless device access with the free Vögtlin Connect app

Alarm, warning and diagnostic features

The information is accessible via Vögtlin Connect app or Modbus

High accuracy, sample rate and fast response

Minimum Inlet required

Custom application profiles

Introducing Vögtlin Automated Dynamics VADy®

With the d·flux multi series, Vögtlin for the first time introduces an automatic real-time calculation of the optimum dynamic range*.

With this user selectable setting, the device dynamically adjusts the highest possible dynamic range under actual conditions. VADy® makes it easy to work with the different gases and applications and offers convenience with optimum device efficiency:

Default dynamic range 1 : 100

1 : 1000 dynamic with VADy® feature available

*available for meter only

Types & Options d⋅flux multi series

d·flux multi meter DFM

Multi-parameter mass flow meter

Flow up to 1400 ln/min

Stainless steel 316L (1.4404)

Modbus communication & analog output

d·flux multi controller DFC

Multi-parameter mass flow controller

Flow up to 1400 ln/min

Stainless steel 316L (1.4404)

Modbus communication & analog output

d·flux multi meter DFM advanced comms

Multi-parameter mass flow meter

Flow up to 1400 ln/min

Stainless steel 316L (1.4404)

With additional Profinet / EtherCAT interface

d·flux multi controller DFC advanced comms

Multi-parameter mass flow controller

Flow up to 1400 ln/min

Stainless steel 316L (1.4404)

With additional Profinet / EtherCAT interface

Technical Specifications d⋅flux multi series

| Measuring Ranges | |

|---|---|

| Standard ranges (air / user adjustable)¹ |

LFE1400 from 0-1000 ln/min to 0-1400 ln/min LFE1000 from 0-700 ln/min to 0-1000 ln/min LFE700 from 0-500 ln/min to 0-700 ln/min LFE500 from 0-350 ln/min to 0-500 ln/min |

| Gases | Max. Bereich | Core | Prime | Prime H2 |

|---|---|---|---|---|

| Air | 0-1400 ln/min | ✓ | ✓ | ✓ |

| N2 | 0-1400 ln/min | ✓ | ✓ | ✓ |

| Ar | 0-1240 ln/min | ✓ | ✓ | ✓ |

| He | 0-1400 ln/min | ✓ | ✓ | |

| CO2 | 0-740 In/min | ✓ | ✓ | |

| CO | 0-1390 In/min | ✓ | ✓ | |

| H2 | 0-2900 In/min | ✓ |

Above are the default gases pre-programmed for each sensor. More gases can be added as options.²

¹ Unless clearly stated, the specified flow ranges are for an equivalent flow of air at 1013.25 mbar a (760 mmHg) and 0 °C

(32 °F). Other common flow, temperature and pressure units can be selected through the Vögtlin Connect app or the

digital communication interface. More information available in the d·flux multi operating instructions.

² Additional gases or gas mixtures can be added to the above standard list. Maximum you can store up to 15 gases per

unit. Stored gases can be replaced by another gas or gas mixture (except for air). Programmed gases/mixtures can be

selected through the Vögtlin Connect app or the digital communication interface.

For other gases, gas mixtures and reference conditions please contact the factory. Only suitable for dry and clean gases.

| Profiles | |

|---|---|

| Customer defined profiles | Up to 15 user programmable profiles Profiles are preset configurations where the customer can set the gas, range, dynamics, totalizers, engineering units and reference conditions for up to 15 different applications |

| Performance Data | |

| Accuracy | A1 Core: ± 0.5% of user full scale ± 1% of measured value. B1 Prime : ± 0.3% of user full scale ± 0.7% of measured value. B2 Prime high accuracy: ± 0.3% of user full scale ± 0.5% of measured value. Coming soon (Hydrogen applications): B3 Prime H2: ± 0.3% of user full scale ± 0.7% of measured value. B4 Prime H2 high accuracy : ± 0.3% of user full scale ± 0.5% of measured value. User full scale = ~70…100% standard range. |

| Media | All gases and gas mixtures that are compatible with the selected materials and for which data is available in the NIST refprop database. Contact the factory for more information. |

| Dynamic range | Fixed dynamics: 1 : 100 for most gases* VADy® dynamics: up to 1 : 1000 (available for meter only) VADy® or a fixed dynamic range can be selected during order process. This setting can be changed at any time using the Vögtlin Connect app. *The dynamic range is gas and pressure dependent, higher pressures means lower dynamic range. |

| Response time | Meter: 120 msec / Controller: 2000 msec (according to SEMI standard SEMI E17-1011)* Update time mass flow value: 10 msec / Sensor sample rate: 1 msec *With optimized filter settings. All filter modes and values can be set through the Vögtlin Connect app or the digital communication interface. |

| Repeatability | ± 0.2% of factory full scale (according to SEMI standard E56-0309) |

| Longterm stability | Typical < 0.2% of measured value / year after tare |

| Power supply | Meter: 15-36 Vdc, (200 mA@24Vdc, regulated) / Controller: 24 Vdc ±10%, (2000mA@24Vdc, regulated) Power in through M8-4P connection or optionally through D-sub connection (ripple should not exceed 100 mV peak-to-peak) We recommend that the body of this unit is properly connected to ground |

| Operation pressure | 1 to 14 bar a |

| Temperature (environment/gas) | -20 to +60 °C (-4 to 140 °F) |

| Humidity gas | 0-95% Rh (non-condensing) |

| Pressure sensitivity | Prime and Prime H2 sensor: <0.05% factory full scale per bar (typical air). Core sensor: <0.08% of factory full scale + 0.1% of measured value per bar (typical air). |

| Temperature sensitivity | <0.02% FFS* per 1 °C of inlet gas temperature @ 7 bar a pressure *Factory Full Scale (maximum flow range of the device) |

| Accuracy temperature | Typically ± 0.5 °C (not certified) |

| Accuracy absolute pressure | <0.5% MV (not certified) |

| Warm-up time | <2 sec for full accuracy |

| Materials | |

| Wetted parts | Elastomers: available now : FKM, EPDM (Meter only). EPDM (Controller, coming in 2023), FFKM Valve seat (coming in 2023). Full FFKM version (on request). Body: Stainless-steel 316L (1.4404). Valve (controller): 316 (1.4401), 416 (1.4005), 430F (1.4104). Inlet filter: Stainless-steel 316 (1.4401), fastening stainless-steel (1.4122) or equivalent. A1 core sensor: Stainless-steel 316Ti (1.4571), silicon, gold, glass, silicone encapsulation, PBT. 30GF, ceramics. B1 Prime sensor: Stainless-steel 316L (1.4404). B2 Prime H2 sensor: Stainless-steel 316L (1.4404) with gold coating. |

| Electronic housing | Powder coated stainless steel |

| Integrated inlet filter | 50 Micron SS316 (1.4401) filter / not customer replaceable/ fastener material SS (1.4122) |

| Wetted part surface roughness | 1.6 Ra µm or better (contact factory for lower Ra values) |

| Integration & Installation | |

| Output signals analog | Linear 4–20 mA or customer defined (max 20 mA) user selectable Linear 0–5 VDC or 0-10 VDC or customer defined (max 10 Volt) user selectable mA output: 740 ohms maximum load resistance Volt output: 1000 ohms minimum load resistance All analog outputs are galvanically separated and protected. If used with analog signals add 0.2% of FFS to the uncertainty |

| Setpoint signals analog | Linear 4–20 mA or customer defined (max 20 mA) user selectable Linear 0–5 VDC or 0-10 VDC or customer defined (max 10 Volt) user selectable |

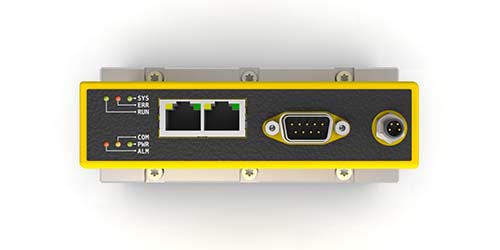

| Output signals digital | RS-485 (Modbus RTU 2-wire) The Modbus address can be set with 2 rotating switches on the outside of the housing. All Modbus settings can be set through the Vögtlin Connect app. |

| Optional Profinet or EtherCAT | Dual Port RJ45 with integrated switch (easy to daisy chain) RJ45 LEDs indicating link and activity on the network / Ethernet speed: maximum 100 Mbit ProfiNet: PROFINET IO specification v2.33 / PROFINET IO devices conformance class B (RT) / Endianness: conform Siemens S7 (big) EtherCAT: IEC standard IEC61158 / Endianness: little Ethernet IP will be available end of 2023. |

| Configuration interface | Bluetooth 4.0 (free Vögtlin Connect app available from Google Play store) |

| Output I/O mosfet | On/off for external shut-off valve or alarm available through M8-4P connector Contact type: mosfet transistor Maximum voltage: 36 Vdc, Max current 500 mA (Polyfuse protected) |

| Electrical connection | 9 pin D-sub male (power and signals) M8-4P connector (open collector output + power) Optional 2 x RJ45 (EtherCAT / Profinet) |

| Process connection | 1″ BSPP female (1″G) Optional ½” BSPP, 1″ Compression or Tri-clamp 50.5mm flange size (ISO) (see accessories tab) |

| Inlet section | None required if our standard inlet filter / conditioner is installed Without filter / conditioner a 10 D straight inlet is recommended The inlet filter can be deselected at time of order |

| Pressure drop | Meter: Standard 400 mbar at factory full scale air venting to atmosphere (with filter / conditioner) Optional: 325 mbar at factory full scale air venting to atmosphere (without filter / conditioner) Pressure drop is dependent on operating pressure (higher pressure = lower pressure drop) For more information please refer to your sales partner Controller: Min. pressure difference required for 1400 ln/min (air) < 2 bar Contact your sales partner for other pressure drop requirements |

| Mounting orientation | All orientations are possible |

| Weight | Meter: 3.7 kg / Controller: 8.7 kg (excluding ethernet and fittings) |

| Safety | |

| Test pressure after production | 28 bar a |

| Maximum overpressure sensor | Core Sensor: 28 bar a, Prime and Prime H2 Sensor: 90 bar a |

| Burst pressure | Meter: 100 bar a / Controller: 70 bar a |

| Leak rate | < 1 x 10-6 mbar l/s He |

| Ingress protection class | IP54 if IP54-D-sub is used (see accessories tab) For optional EtherCAT/Profinet: IP40 |

| Certifications | |

| EMC | IEC/EN 61326-1, IEC/EN 61000-6-2/4 |

| ATEX certification | None |

| Material certificates | To be released in 2023 (available for meter only) |

| FDA compliance | To be released in 2023 (available for meter only) |

| PED | Fully compliant. Since the unit has 1″ process connection, complies with the SEP as defined in article 4, paragraph 3 of the Pressure Equipment Directive (PED) (2014/68/EU) |

| RoHS / REACH | All components comply with Directive 2002/95/EC (RoHS) and the REACH guidelines |

| Warranty | 3 years, except when using certain corrosive / dangerous gases (HCL, CL2, F2, H2S, SO2) |

| Vögtlin |

|---|

| Instruments |

This is a text block. Click the edit button to change this text.

Power, plugs and cables

IP54-D9-sub connector

This plug connects to the male D-sub on top of the d·flux unit to connect the signals and power.

With this plug installed and the cap on the DIN M8 connector the integrity rating of this unit is IP54.

Available as plug only (solder connections inside) or with 2 meter cable with fly leads.

Maximum current 2 amp.

Art-N° 328-2093 – IP54-D9-sub connector (IP54 rated, 9 solder connections, no cable)

Art-N° 328-2094 – IP54-D9-sub connector (IP54 rated with 2 meter cable and fly leads (9))

IP20-D-sub connector

Available as plug only or with 2 meter cable (for indoor IP20 applications only)

Art-N° 328-2102 – IP20-D9-sub connector (IP20 rated, 9 solder connections, no cable)

Art-N° 328-2103 – IP20-D9-sub connector (IP20 rated with 2 meter cable and fly leads (9))

IP40-Power supply

In: 100-240 Vac / Out: 24 Vdc, 2.2A with M8-4pin connector

Not suitable for IP54 applications, for indoor IP40 applications only. Suitable for meters and controllers.

Used to configure the d·flux on your desktop with the Vögtlin Connect app

Art-N° 328-2361 – Table top power supply (EU plug)

Art-N° 328-2362 – Table top power supply (US plug)

Art-N° 328-2363 – Table top power supply (GB plug)

Art-N° 328-2364 – Table top power supply (AU plug)

Art-N° 328-2365 – Table top power supply (CN plug)

IP20-RS485 to USB

A simple way to connect your d·flux over Modbus to your PC

Consisting of 1) RS485 to USB converter (no external power required for converter), 2) a USB-A (version 2.0) connection to your PC and 3) a 9 pin D-sub female connector to the d·flux / Total cable length 3 meters.

USB 2.0-B female to 1 x 9 pin serial RS422/485 male

Chipset: FT232HL, SP3078EE, Dimension: 80 x 72 x 23 (LxWxH)

Power supply for the d·flux needs to be purchased separately – not included in this kit.

Art-N° 328-2112

IP54-M8 plug

Available as plug only or with 2 meter cable. M8-4pin plugs are suitable for IP54 applications.

Maximum current 4 Amp.

Art-N° 328-2096 – IP54-M8 connector (4 Pin straight female with screw terminals and cable gland)

Art-N° 328-2097 – IP54-M8 connector as above but with 2 meter cable with fly leads

IP54-M8 cap

Cap to seal off M8 connection if not used (required for IP54 protection).

Supplied one with every unit. Only required when IP54 protection is lost or damaged

Art-N° 632-1221 – IP54-M8 cap (to close off/open not used M8 connector)

Fittings

1” Compression fitting

Stainless Steel Compression Tube Fitting, Male Connector, 1”. Tube OD x 1” BSPP tread

Male ISO Parallel Thread / Material SS316 (1.4401) including O-rings

Optional 3.1 Certificate upon request when order is placed

Art-N° 328-1254 – FKM

Art-N° 328-1255 – EPDM

DN50 Tri-clamp

Tri-clamp connection 50.5mm flange (ISO), to 1” BSPP tread

Material 316L (1.4404) including O-rings

Art-N° 328-1426 – FKM

Art-N° 328-1427 – EPDM

Reducer 1” BSPP to ½” female BSPP

Reduced process connections from 1” BSPP male tread to 1/2” BSPP female

Material 316Ti (1.4571) including seal rings

Art-N° 328-1257 – FKM

Downloads d⋅flux multi series

The new Vögtlin Connect App

The Vögtlin Connect app can be used with Android phones and let’s you easily and securely (password protected) connect to your d·flux device.

Vögtlin Connect is a user friendly configuration software and offers the adjustment of many device parameters:

| Bluetooth readable / adjustable variables | Read | Write |

| Create & edit profiles (set of settings) | YES | YES |

| Flow range & dynamic range | YES | YES |

| Filter settings | YES | YES |

| Alarms and warnings | YES | YES |

| Analog in/output configuration | YES | YES |

| Function of push button* | YES | YES |

| Read current values | YES | |

| Show Graphs | YES | |

| Totalizer (read, select, reset) | YES | YES |

| Node / slave address setting | YES | YES |

| I/O for external valve on / off | YES | YES |

| Restart device | YES | |

| Password protection of unit | YES | YES |

| Factory reset | YES | |

| PID and valve parameters | YES | YES |

* The external push button on the device can be programmed for one of the following functions: Device restart, measurement on/off, warning reset or tare (long press). Activation/Deactivation of Bluetooth® connection (short press).

The app works with Bluetooth® and can be downloaded for free from Google Play store.